Types of Building Materials and Their Uses: An Integrated Engineering Perspective in Light of Saudi Architectural Development

In the foundation of every successful construction project, building materials stand as a core determinant of structural integrity, energy performance, cost efficiency, and sustainability. In Saudi Arabia—a country with a diverse climate and ambitious urbanization goals—this topic holds particular importance.

Understanding the properties and evolution of construction materials is no longer a luxury, but a technical imperative, especially amid the country's drive for high-performance, code-compliant, and environmentally responsive building practices, as seen in Vision 2030 and smart city initiatives like NEOM.

I. Historical Evolution of Building Materials in Saudi Architecture

Traditional Saudi architecture was deeply rooted in locally available materials:

- Mud bricks in Najd and Al-Ahsa for their insulation in hot climates.

- Limestone and volcanic stones in the Hijaz and the southern regions.

- Palm trunks and fiber in coastal areas for structural and shading purposes.

The post-oil boom era (1970s onward) marked a shift toward reinforced concrete, steel, and manufactured blocks, influenced by Western architectural models and rapid urban growth. In recent years, a return to regionally contextual architecture has emerged, supported by modern materials like engineered clay, insulated blocks, green concrete, and materials aligned with Saudi Building Code (SBC) and global sustainability standards.

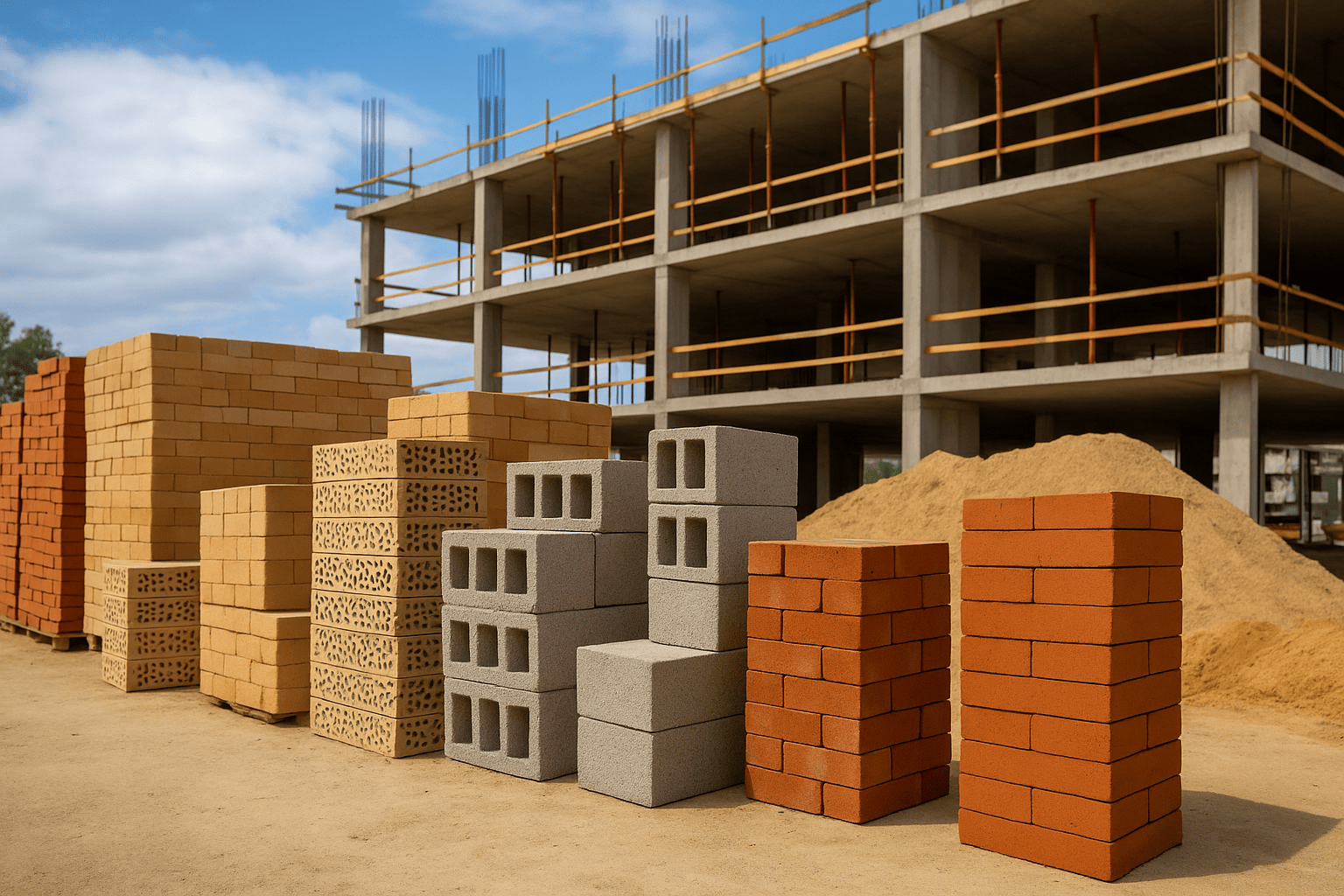

II. Engineering Analysis of Key Building Materials

1. Red Clay Brick

- Physical Properties: Moderate porosity, fire resistance, low thermal conductivity, minimal expansion.

- Applications: External walls in residential buildings, traditional-style villas, hotels.

- Advantages:

- Excellent thermal performance for desert climates.

- Lifespan of over 75 years.

- Minimal maintenance.

✅ Locally sourced from central and southern Saudi brick kilns.

2. Concrete Masonry Units (CMU)

- Types: Solid – Hollow – Insulated.

- Engineering Properties:

- Compressive strength up to 7.5 MPa.

- Fire resistance up to 4 hours (per ASTM C90).

- Fast installation and adaptable in modular construction.

- Applications: Load-bearing walls, partitions, perimeter walls.

✅ Widely used in schools, office buildings, and residential compounds.

3. Autoclaved Aerated Concrete (AAC)

- Properties:

- Density: 300–800 kg/m³.

- Thermal conductivity (λ): ~0.12 W/mK.

- Easy to cut, fire resistant, moisture durable.

- Applications: Interior and exterior walls, especially in energy-efficient projects.

- Benefits:

- Reduces structural loads by ~35%.

- Saves up to 30% on HVAC-related energy consumption.

✅ Widely specified in NEOM, Qiddiya, and other smart city frameworks.

4. Reinforced Concrete & Steel

- Engineering Values:

- Concrete compressive strength: 25–40 MPa.

- Steel tensile strength (Fe500): ≥ 500 MPa.

- Applications:

- Foundations, structural frames, precast and prestressed systems.

- High-rise towers, infrastructure, and industrial facilities.

- Design Considerations:

- Requires proper expansion joints.

- Needs anti-corrosion protection, especially in coastal zones.

📚 Reference:

- ACI 318-19: Structural Concrete Code

- SASO 2310: Rebar standards for construction

5. Architectural Finishing Materials

- Gypsum Board: Ideal for partitions and ceilings with thermal and acoustic insulation.

- Natural Stone / Marble: Used in interior and façade cladding for prestige and durability.

- Aluminum Composite Panels (ACP): Lightweight and weather-resistant for modern building skins.

III. Modern Trends in Saudi Building Materials

1. Low-Emission Materials (Low-VOC)

- Used in paints, adhesives, and insulations.

- Certified under Saudi Green Building guidelines.

2. Smart Materials

- Photochromic glass, reflective membranes, thermally adaptive coatings.

3. Prefabrication & Modular Construction

- Up to 60% time savings in project execution.

- Recommended by the Ministry of Housing and the National Building Technology Center.

At Ruaya Al-Dar Contracting, we don't merely build structures—we engineer lasting value. Our approach combines in-depth material evaluation with climate-conscious design strategies, ensuring each project meets the highest standards in safety, energy performance, and lifecycle cost-efficiency.

With over a decade of experience, strategic supplier partnerships, and a dedicated team of engineers, we support your project from concept to completion—delivering excellence that stands the test of time.